Mass spectrometry (MS) has become an indispensable tool during manufacturing process development, also known as CMC (Chemistry Manufacturing and Controls) development, for biologics. Information about product-related variants (such as post-translational modifications (PTMs)) and process-related impurities (such as host cell proteins (HCPs)) can be extensively characterized by MS to understand process performance and product quality. The in-depth data provided can play a key role in defining and understanding the Critical Quality Attributes (CQAs) which need to be well-controlled by the manufacturing process and closely monitored by the analytical testing panel to ensure specifications are met. MS attribute data is also a key component in regulatory submissions, including the Elucidation of Structure and Manufacturing Process Development (especially process comparability) sections. With recent development of new methods and instrumentation, MS is finding a wider usage in the regulated release testing of Good Manufacturing Practices (GMP)-produced drug substance, such as for identity testing, target attribute or impurity monitoring, or multi-attribute-methods (MAM). State-of-the-art MS technologies also benefit proteomics studies with higher sensitivity, lower detection limit, and faster throughput.

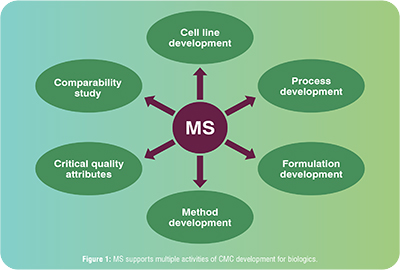

After a lead protein design is selected for clinical trials, biologics manufacturing (also known as chemistry manufacturing and control, or CMC) development activities commence. CMC development encompasses the entire manufacturing process of the drug substance (DS) and formulation of the drug product (DP) at a scale and quality sufficient for human use in clinical trials or as a commercial product. The initial application for use of a lead protein in a clinical trial requires the submission of an Investigational New Drug (IND) or Clinical Trial Application (CTA) to the respective government agency where the trial is planned. The process and analytical development teams at the sponsor company ensure the quality and safety of the product to be used for clinical trials by a comprehensive workflow of identifying Critical Quality Attributes (CQAs), setting product specifications as part of a control strategy for ensuring the CQAs are at required levels, and demonstrating process consistency by comparability studies. As shown in Figure 1, MS is a valuable tool supporting most activities of Biologics CMC development, including but not limited to cell line development, process development including upstream (bioreactor expression) and downstream (purification) stages, formulation development of the drug product (the final presentation, including vials and devices, as well as biotherapeutic and excipients), critical quality attribute (CQA) characterization, comparability studies, and any additional studies such as investigations of process outliers or lot failures.

Mass spectrometry is a versatile tool for answering questions like “What does the molecule look like?”, or more specifically, “what is the amino acid sequence/primary structure of the protein molecule?” Peptide mapping and intact mass are two of the most common approaches for MS assays that support extended characterization of drug candidates. For peptide mapping experiments, protein samples undergo digestion by incubating with protease(s) prior to separation by liquid chromatography (LC) and mass analysis by MS. For intact mass experiments, protein samples do not undergo proteolysis; instead, samples are diluted, and the mass analyzed for the intact molecules or subunits. Intact MS is useful because it quickly verifies the primary sequence and most-abundant post-translational modifications (PTMs) of the protein. The accurate measurement of masses by most modern MS instruments ensures reliable identification of the major component of the drug and most deviations from its expected structure due to the impact on molecular mass of the protein.

MS is used to detect sequence variants (SVs) to support cell line development in the early stage of CMC development. SVs are unintended errors in the amino acid sequence of the biotherapeutic protein caused by substitutions, deletions, and/or insertions of nucleotides in the DNA encoding for our protein within the host cell line.

DNA mutations can result in missense (incorrect amino acid being substituted), non-sense (a truncation site for expression of the protein) or frame shift mutations (where the reading frame shifts, dramatically changing the amino acid sequence), potentially impacting the quality, safety, and efficacy of biotherapeutic proteins. It should be noted that MS cannot detect silent mutations, therefore SV screening by MS as well as orthogonal nucleotide sequencing methods such as Next Generation Sequencing of mRNA (NGS) or Sanger sequencing of cDNA are routinely performed during the clone selection stage to ensure that the final lead clone used has no encoding mutations. Using both approaches simultaneously is beneficial over nucleotide sequencing approaches alone, as MS provides a direct measure of SV impact on the final protein product, whereas nucleotide approaches may not indicate if the mutant form is expressed or co-purified.

MS also provides valuable insights to support both upstream and downstream manufacturing process development. During upstream development, many bioreactor culture conditions such as pH or temperature may lead to differences in analytical attributes of the therapeutic protein, such as the charge profile distribution (measured by isoelectric focusing or ion exchange chromatography). MS can be leveraged to identify the specific modification differences of the therapeutic causing a shift in the profile, such as deamidation of a specific asparagine, or modification of the C-terminus of the protein. This knowledge can allow both a quality risk assessment and understanding of the root cause of the difference

Feed is another upstream parameter that may directly impact product quality. For example, saccharide supplementation of the feed impacts the glycan structure of the final product. MS measurements can provide rapid glycan measurement while optimizing the feeding strategy to achieve the desired glycosylation profile. Sub-optimal levels of amino acid feed additives may lead to misincorporation of a specific amino acid in the protein sequence by “mischarging” of the incorrect amino acid onto a tRNA during mRNA translation into protein. Therefore, beyond screening for mutations, MS is often used for detecting SVs resulting from feed parameters and ensuring their appropriate control from the final process.

Biologic formulation development includes optimization of buffer, pH and excipients to ensure optimal stability of the protein delivered in the desired form and route of administration to the patient, be-it a glass vial for intravenous infusion, or an autoinjector for subcutaneous self-administration at home. Real-time stability studies test the protein response to various condition changes, including the concentration of the therapeutic and excipients in solution, or the delivery devices intended to be used. MS plays a key role in structural characterization of any degradation products observed such as covalently induced aggregation and clipped species. It can provide high-accuracy information about degradation products such as molecular weight of dimer aggregates, and cleavage site locations. Furthermore, MS can be used for host cell protein (HCP) characterization. HCPs are endogenous proteins from the host organism used to express the therapeutic protein which may co-purify with the desired protein product. Lipases are a class of HCP that may cause degradation of polysorbate 80, a common excipient which may be needed for stability of the therapeutic, especially in formulation with high concentration DS. Trace level lipases may pose a common risk to the drug quality. MS-based HCP identification methods can be used to determine if lipase contamination is responsible for polysorbate degradation observed during formulation development.

It is well understood that for a new drug product, certain physical, chemical, or biological properties should be within an appropriate range to ensure the desired product quality. These attributes, according to the Quality-by-Design (QbD) framework regulatory agencies have set, are known as Critical Quality Attributes (CQAs). Therefore, a CQA study/ assessment is an important exercise during CMC development. During early and clinical drug development, degradation pathways and potential CQAs are explored using accelerated stability and forced-degradation experiments, as well as integrating knowledge learned during formal stability studies and process development. A good understanding of CQAs is especially important for a QbD methodology, as well as process validation, to achieve desired product quality through risk assessment and valid control strategies.

During CQA assessment studies, various analytical assays are used to examine molecular changes of the therapeutic in terms of high molecular weight species (HMW), low molecular weight species (LMW), charge variants, oxidation, deamidation, isomerization of aspartic acid, deconjugation of drug payloads (for antibody-drug conjugates, for example), etc. With peptide mapping and intact-mass MS, modifications of the protein’s amino acid residues or clipping products are determined, and their levels quantified. The question of “How does the molecule degrade?” can generally be answered, which can then be correlated with our understanding of structure-function relationship and functional assays (sometimes including in vivo studies) as deemed necessary as part of an attribute risk assessment. During post first-in-human (FIH) commercial process development, further forced degradation studies are often carried out to assess multiple degradation pathways and impact to product quality and functionality.

Separations methods are commonly used for release testing assays for a Good Manufacturing Practices (GMP) manufacturing campaign, producing material for human use. This is attributed to their ability to measure product-related variants accurately and sensitively. These methods are set with specifications to monitor CQAs and to ensure process consistency. MS instruments are heavily used to support analytical method development, providing insights such as chromatographic/electrophoretic peak identification, and correlating the attributes measured with the structure-function understanding of the therapeutic.

Size exclusion chromatography (SEC) is developed to monitor the amount of HMW aggregates within biologics. MS can support characterization of the biologics to potentially help understand the mechanism of aggregation (high oxidation, crosslinks, clipping, etc.). Additionally, MS data can confirm where an LMW truncation site is located and thus assess its location to its potential impact on potency. MS is also used in profiling PTM variations relative to binding sites and helps with understanding their impact on mechanism of action (MOA).

MS is also helpful for peak characterization and identification for capillary gel electrophoresis (CGE) methods. A good example is the confirmation of a shoulder peak identity as non-glycosylated protein, which directly informs whether this peak may be considered part of the “main peak”, or a product-related impurity, when integrating electropherograms. The high-resolution of CGE can also separate and quantify specific cleavage products of the protein backbone, whose identity can be confirmed by MS. MS is also used to correlate levels of PTMs of a biotherapeutic in charge-based separation methods such as isoelectric focusing (IEF) and cation exchange chromatography (CEX). Some common reasons for the increase of acidic peaks are deamidation of asparagine and glycation, while oxidation, C-terminal lysine, and aglycosylation lead to increase of basic peaks. Using MS to identify these modifications is a critical step to establishing phase-appropriate specifications of these release methods as these chemical changes may or may not be CQAs.

In addition, it is common to use MS instruments to support the development of hydrophilic interaction chromatography (HILIC) methods for measuring released N-glycans. Individual glycan peaks can be directly identified by their masses, which is important as some classes of N-glycans such as high-mannose, sialylated, afucosylated, or alpha-Gal-containing glycans are known to impact patients by their effect on pharmacokinetics (especially half-life), potency, or immunogenicity and should thus be well-characterized and controlled.

MS plays an essential role in the extended characterization of any new biologic, deciphering the chemical structure down to single amino acid residue level. Data are documented in the IND/CTA filing sections, especially in Module 3, Section 3.2.S.3.1 Elucidation of Structure, as part of the DS Quality section. Extended characterization testing including MS is also usually performed upon qualification of a new reference material.

A formal analytical comparability study is reported when filing an IND/CTA or biologics license application (BLA) amendment for a manufacturing process change (change in cell line, upstream/downstream process change, location change, etc.). Analytical comparability provides justification supporting the process change by demonstrating no impactful changes to the attributes of the biotherapeutic. Similar to the characterization section of the initial IND filing, LC-MS data – both peptide mapping and intact mass – support the extended characterization portion of the comparability study and are captured in Module 3 of the filing, Section 3.2.S.2.6 Manufacturing Process Development for DS and Section 3.2.P.3.5 Process Validation and/or Evaluation for DP. Comparability studies are performed as side-by-side extended characterization for the DS or DP material between the originally filed process and the new process. Comparability parameters to monitor using LC-MS include product-related variants and molecular masses of intact and reduced protein subunits, among other assays. Together, MS data combined with structure-function understanding and other analytical methods can provide a strong argument for process comparability and avoid the need for additional clinical trials to demonstrate comparability, especially in early clinical studies.

In the past decade, LC-MS-based proteomics approaches have emerged as informative impurity profiling methods for biotherapeutics, with extensive studies and applications in the field of HCP characterization. Trace levels of certain HCPs may elicit immune responses in patients, affect drug efficacy, or degrade the product over time. It is a requirement from regulatory agencies to demonstrate effective removal of these impurities in the final DS by the downstream process steps.

HCP content is also monitored as an in-process parameter to understand the clearance of each downstream processing step. LC-MS “shotgun” proteomics is adopted in addition to the well-established and widely used enzyme-linked immunosorbent assay (ELISA) for total-HCP measurement. Proteomics approaches identify HCPs by digesting protein samples into peptides followed by tandem MS (MS/MS) and database searches against the entire proteome of the host cell species. Semi-quantitation of individual HCP species can be achieved by employing the “Hi-3” quantitation strategy. MS methods are useful when comparing HCP profiles between different conditions such as two different processes, demonstrating clearance of individual “problematic” HCP species (through different purification stages, etc.), and picking up sub-ppm levels of HCPs in so-called “clean” samples such as final DS.

However, one of the biggest challenges of MS technology to achieve the desired sensitivity for HCP detection is the limitation of the dynamic range required for HCP test samples. HCPs are typically present within biotherapeutics at an approximately million-fold excess of the therapeutic protein, posing a challenge for most analytical approaches. To address this challenge, innovative technologies for sample preparation are developed for enriching HCPs to minimize the difference between the amounts of HCPs present versus biotherapeutic. Meanwhile, improvements on MS instrumentation offer better sensitivity for detection of low abundance species (i.e., HCPs) in the presence of a complex matrix.

Mass Spectrometry Has Increasing Application in the Quality Control Environment.

With the advancement and accessibility of technology and high throughput capability, there is a recent trend of employing MS in quality control (QC) environment. In previous years, MS was rarely used in the QC environment due to its complexity and the lack of MS-trained personnel. MS application in QC is rapidly expanding as no-configuration-needed MS instrumentation and QC-compliant data acquisition and processing software become more readily available.

One such application is the use of intact mass analysis for identity (ID) confirmation of the biologics, especially in the early phase of the program development. Compared to conventional ID methods like ELISA and peptide mapping, intact MS ID method has the advantage of less-labor intensive workflow and specificity. Intact MS can be used as one of the ID methods in the scenario where health authorities require orthogonal ID strategies.

The advantages of MS over other conventional chromatographic and electrophoretic assays become more significant when it comes to characterization of complex biologics molecules such as fusion protein, bi- and tri-specific antibodies, complex glycoproteins, antibody-drug conjugates, viral vectors, peptide therapeutics, and other novel modalities. The complexity of these molecules often mean that conventional approaches do not provide as informative results since many PTMs may contribute to multiple peaks simultaneously, making these approaches less sensitive to changes in the product. Meanwhile, MS can provide site-specific PTM information even with highly complex constructs. These PTMs, if identified as CQAs, could potentially impact product efficacy and safety (as described previously). Implementation of MS based methods for release and stability testing has been reported for monitoring various attributes such as oxidation and deamidation levels.

Another emerging application is leveraging MS for multi-attribute-method (MAM) in the QC environment. MAM is an LC-MS based method which enables the detection and monitoring of multiple product quality attributes (PQAs) simultaneously while replacing more well-established chromatographic or electrophoretic assays. The MAM workflow includes the discovery phase for targeted peptide library generation based on retention time and mass information of all the quality attributes, followed by the monitoring phase based on the library and new peak detection and analysis. Recently, validation of MAM as a QC method has been reported for relative quantitation of target PQAs.

Improvements in the performance and availability of high-end commercial instrumentation have made MS an increasingly popular approach for biologics characterization in the pharmaceutical industry.

Through the past decade or so, MS instrumentation has witnessed great advancement towards higher sensitivity, better resolving power, lower detection limit, and faster throughput. State-of-the-art technologies effectively boost the capability of mass spectrometers for handling complex therapeutics samples. The latest Orbitrap mass spectrometer model, branded as “Astral” by Thermo Scientific, combines three mass analyzers within one instrument, including the novel Astral analyzer (featuring ion mirrors) for fast and sensitive measurements. The greatly enhanced sensitivity, throughput, and data quality from this instrument may provide potential for more comprehensive characterization of host cell proteins in biotherapeutics products.

Ion mobility mass spectrometers couple a high-resolution mass analyzer with ion mobility separation, making it particularly useful for the analysis of isomers and conformers. The recently launched timsTOF technology from Bruker, which incorporates a Trapped Ion Mobility Spectrometry (TIMS) device at the front of a quadrupole time-of-flight (QTOF) mass spectrometer, is claimed to achieve a near 100% duty cycle for high sensitivity, high speed proteomics. In addition, collision-induced unfolding (CIU) workflow of native-like protein ions followed by ion mobility spectrometry (IMS) continues to expand its utilization due to its ability to rapidly characterize protein conformation and stability. It has proven useful in probing the higher order structure of antibody therapeutics.

Furthermore, enhanced MS/MS technologies also facilitate ion fragmentation for increased sensitivity and deeper coverages for proteomics studies. The electron activated dissociation (EAD) fragmentation technology employed on the SCIEX ZenoTOF system is marketed for its extended utility on all molecules type from singly charged to multiply charged ions, making it outperform either CID/HCD (collision-induced dissociation/high-energy collisional dissociation) or ECD (electron capture dissociation) technology alone. EAD can also aid in identification of labile PTMs such as glycosylation, phosphorylation, sulfation, etc. Overall, continuing improvement of MS instrumentation performance is expected to meet the challenges of complex next-generation therapeutics.

In conclusion, mass spectrometry techniques are under continuing development to enable more routine and specialized support of all phases of biologics CMC development. Not only has MS been enabling faster, higher-accuracy measurements in areas like process and formulation development, CQA control strategy, method development and regulatory filings, but it has also been expanding to more specialized applications such as HCP profiling and GMP release testing within the QC environment. As MS instrumentation and performance continue to improve, MS will undoubtedly be playing a more important role for biologics development in the pharmaceutical industry.